Developed with the portable producer in mind, the plant was designed with an emphasis increasing plant efficiency, reducing size and weight, and lowering the overall cost of ownership by increasing in-spec uptime production and reducing maintenance and downtime.

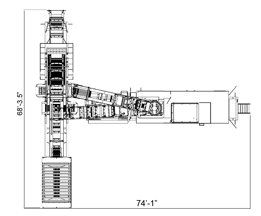

Consisting of an ELRUS MS612 6x12’ 3-deck feeder screen plant and a self-contained Sandvik 200 H.P. CH430 cone crusher with ASRi automated cone control.

These units are engineered to handle large loads in comparison to their smaller size and are able to get into locations that a larger more typical crushing spread wouldn’t be able to go. Both plants feature run-on hydraulic leveling and hydraulic adjustable onboard feed and discharge conveyors to facilitate rapid mobilization and optimize plant efficiency.

The ASRi2.0 has a user friendly, simple to use graphical user interface (GUI) with a touch screen and automatically controls the crusher allowing the operator to obtain the highest rate of reduction and improved particle shape while protecting the equipment from overload and overflow while also monitoring for other events that could occur, allowing ample time to make changes and adjustments to prevent possible damage.

Two chassis to pull

Two chassis to pullChassis #1:

ELRUS Feeder-Screen (36” Feeder, MS612 - 6x12’ 3-Deck High-capacity Multi-slope Screen)

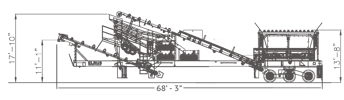

Chassis #2

Sandvik CH430 Cone Crusher, 36” In/Out Conveyors, Control Centre Enclosure

These units are engineered to handle large loads in comparison to their smaller size and are able to get into locations that a larger spread would be unable to fit into.

Multi-slope screen technology developed by ELRUS combined with smart crusher technology from Sandvik enables these plants to run at maximum efficiency and allows a smaller physical size plant without sacrificing production volumes.

Travel Weights & Dimensions

Travel Weights & DimensionsAxle: 55787 lb (19,472 kg) Pin: 42929 lb (19,472 kg)

Length: 65'-7"

Height: 13'-10"

Width: 12'-4"

ELRUS Feeder-Screen (36” Feeder, MS612 - 6x12’ 3-Deck High-capacity multi-slope Screen)

Axle: 51,177 lb (23,213 kg) Pin: 33,605 lb (15,243kg)

Length: 69’

Height: 14’

Width: 12’-5”