- About

- Equipment

- Parts

- Service

- Contact

- Blog

- In-Stock

- Mining

- Resources

- Photo Gallery

Jaw Crushers are used extensively throughout the world by the aggregate, mining and

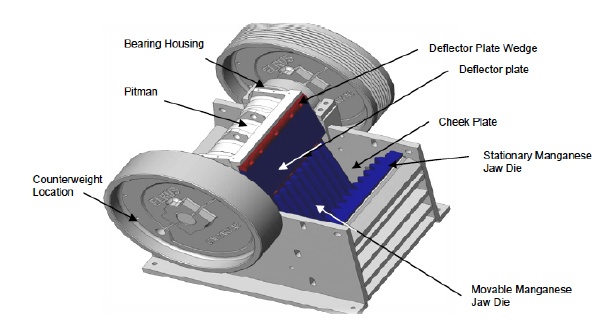

This style of crusher uses compression to crush rock by squeezing it between two jaws: one stationary and one movable. The movable jaw (Pitman) is attached to an eccentric shaft that causes it to move in a reciprocating motion. Rock enters the crushing chamber from the top and moves through the chamber, which gets narrower as it gets

Typical applications:

ELRUS manufactures Single Toggle, Heavy Duty Overhead Eccentric Jaw Crushers. Designed and engineered to exacting specifications, they feature manufactured heavy duty jaw boxes and cast pitmans that are ruggedly built and stress relieved before final machining. ELRUS jaws crushers are available in sizes: 1536, 2036, 2236, 2442, 2054, 3042, and 3054.

ELRUS manufactures Single Toggle, Heavy Duty Overhead Eccentric Jaw Crushers. Designed and engineered to exacting specifications, they feature manufactured heavy duty jaw boxes and cast pitmans that are ruggedly built and stress relieved before final machining. ELRUS jaws crushers are available in sizes: 1536, 2036, 2236, 2442, 2054, 3042, and 3054.

ELRUS Jaws Feature:

Welded Steel Frame

construction 2-2.” steel plate welded

Cast Steel Pitman

1 3/4"-2.” cast steel construction which has been machined to give a closely toleranced fit with other components. The pitman also features a replaceable plate to help protect the barrel from damage due to oversize or slab type material.

Bolt-on Pitman Lip

All ELRUS jaw crushers feature Bolt-On Manganese Support Lips. The bolt-on lips

Spherical Roller Bearings

All jaw crushers come with off the shelf spherical roller bearings for both the pitman and the frame. The pitman bearings are oil lubricated and the frame bearings are grease lubricated from a central location to eliminate the need to shut down for lubrication.

Flywheels

One piece cast flywheels in 48” or 60” diameter sizes. Hydraulic Jaw Adjust with Shims Jaw crusher settings can be easily changed with our standard hydraulic pump used to take the pressure off. This allows you to add or remove shims as needed for the correct setting.

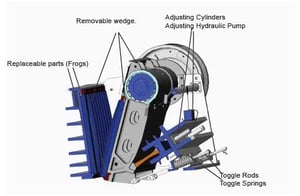

Optional: Hydraulic toggle with tramp iron relief system Replaces the toggle plate. Pressure relieves to allow passage of material that is not crushable

Replaceable Parts

ELRUS has designed our jaw crushers to include replaceable parts that make maintenance simpler. These parts include a

ELRUS has designed our jaw crushers to include replaceable parts that make maintenance simpler. These parts include a

The ELRUS Primary Jaw Plant is an excellent choice for the producer that requires quick setup and mobility with a medium size jaw plant

Jaw Plant Features:

Options:

Improve Primary Crusher Efficiency