- About

- Equipment

- Parts

- Service

- Contact

- Blog

- In-Stock

- Mining

- Resources

- Photo Gallery

As temperatures drop below freezing, any moisture on a conveyor belt can quickly become a problem for a producer trying to keep the belts turning. The accumulation and buildup of ice can lead to problems like material slippage and slide back on the belt, frozen and seized rollers, pulley’s and idlers, torn belts, premature wear and excessive stress on the equipment, let alone your piece of mind.

Don't let old man winter shut down your operation. The right belt heater will help reduce downtime and provide a safer workplace for everyone on site. Basically there are two types to choose from.

As the name implies, fuel fired heaters burn fuel, most typically fuel oil, natural gas and/or propane. They are available for belt widths from 36" to 60"

Instant Shutdown

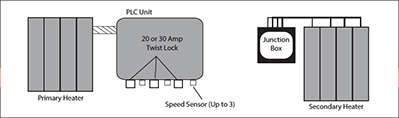

Heater operation is controlled by a motion sensing device that stops the heater even if the belt begins to slow down. A target is welded to the end of an idler or tail roll, a sensor then detects the rotation of the roll allowing the heater to operate. if there is no rotation the heater stops.

Thermostat Controlled

The thermostat is located inside of the air filter housing which protects it from the elements and prevents unauthorized operation. The

thermostat is set to the desired operating temperature, then if the belt is running and the temperature drops to the setting the heater will come on. If the temperature rises above the setting the heater stops.

Adjustable Heat Output

Heat output is adjustable from 35,000 - 400,000 BTU’s on small models and 100,000 - 800,000 BTUs on larger units. Custom designs

feature 1,000,000 plus BTU’s as required.

Remote Applications

Remote models allow the combustion chamber to be located 40 feet or more from the burner control unit depending on the BTU requirements. This system comes with equipped with 11 ft. of remote tube standard.

Additional tube to be specified at time of order.

Belt Heaters Features: