- About

- Equipment

- Parts

- Service

- Contact

- Blog

- In-Stock

- Mining

- Resources

- Photo Gallery

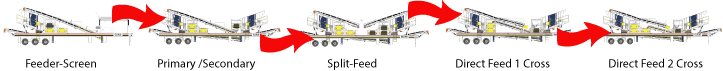

Reconfigurable to any of the options on this page as your needs change. (More configurations coming in future weeks let us know your needs and we will find a way to build it for you)

Design and build the plant that YOU WANT – Reconfigure as you grow or your needs change.

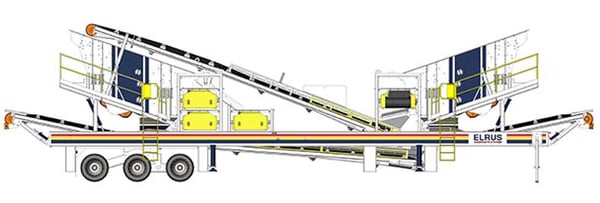

This configuration gives you the benefits of a screen plant and a feeder plant on one chassis with the added benefit that it can be reconfigured into any of the configurations shown below at any time with the purchase of a few additional components.

This plant can grow or change with you and your business needs.

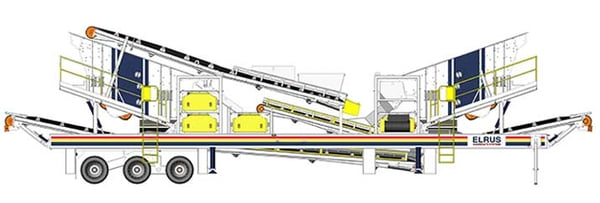

The power of a Primary/Secondary screen. Deal with the large rock and fines stripping on our New Primary MS612 screen and send the rest to the finishing screen for final sizing and recirculation with any cone.

The power of a Primary/Secondary screen. Deal with the large rock and fines stripping on our New Primary MS612 screen and send the rest to the finishing screen for final sizing and recirculation with any cone.

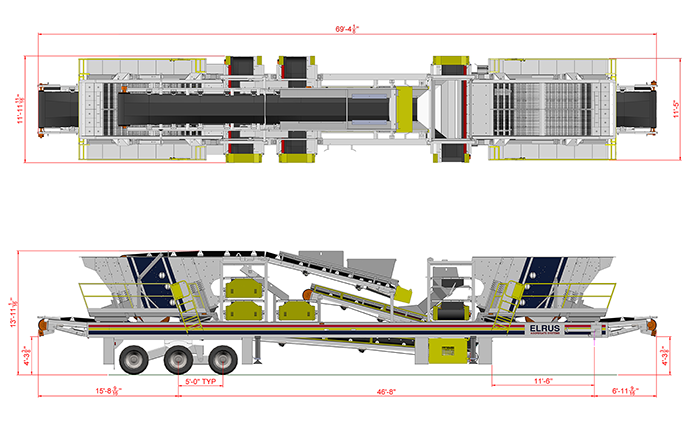

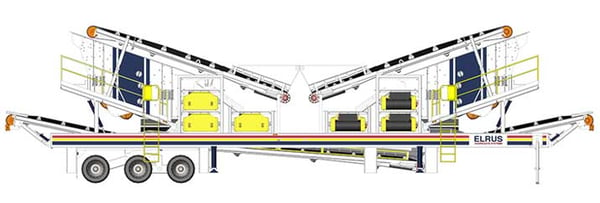

Double your screening surface area, increase product versatility Use One or Two cones to Size up to 1600 tons per hour (Product dependant) single load travel.

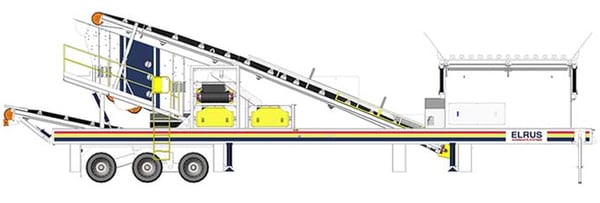

The primary screen separates rock from sand and removes unwanted fines before the finishing screen. All three decks go to the cone and the fines that pass the bottom deck are discharged to a stockpile.

The smaller stone that comes off of the decks promotes rock on rock crushing and helps reduce liner wear and improve fracture rate.

The finishing screen is more efficient because all of the material on it comes from the cone return and has been pre-screened and sized by the primary screen. Three cross-conveyors add versatility and can produce up to three products.