ELRUS | Sandvik CH440 Hydrocone Crusher

The Sandvik CH440 Cone crusher is an advanced design that features a small footprint and high capacity in relation to size. The CH440 offers high reduction efficiency and very good product shape.

The Sandvik CH440 Cone crusher is an advanced design that features a small footprint and high capacity in relation to size. The CH440 offers high reduction efficiency and very good product shape.

With hydraulically adjustable CSS, computer automation, and a choice of several different crushing chambers, the CH440 Cone crusher is versatile, user-friendly and highly productive.

The CH440 Cone crusher can be matched to changes in production through the selection of crushing chamber and eccentric throw. Sandvik cone crushers are ideal for secondary and tertiary crushing and the compact and easy-to-service design also makes them a perfect choice for mobile, wheel portable and permanent installations.

Features and benefits

- Excellent versatility due to a wide range of chambers with different feed acceptance

- Adjustable throw give the possibility to fine tune the performance to match the desired need

- Full control of the process

- Easy to maintain

- Extremely reliable

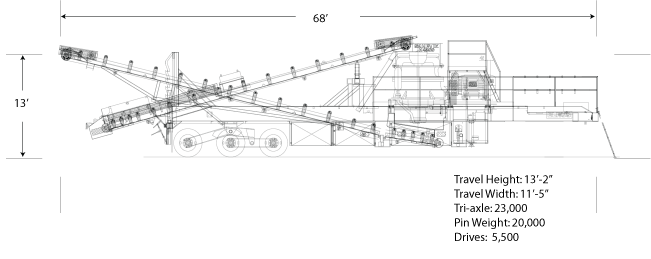

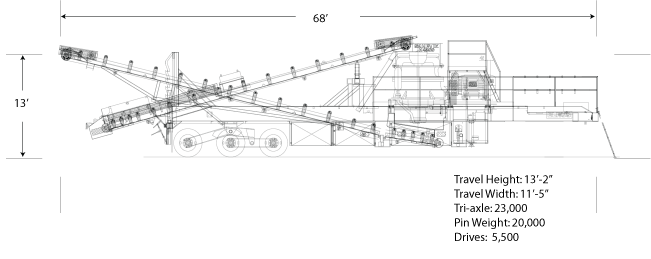

Chassis Features:

- 21” WF Strapped and cambered main frame c/w Six (6) blocking legs

- ELRUS Heavy Duty Tri-axle walking beam suspension

- Floating subframe for cone & motor c/w 6 rubber compression mounts

- Rock box style under cone hopper

- Platform and stairway for cone inspection

- Complete guarding for cone drive and conveyors

- Fixed walkway on both sides of cone and across front of chassis

- Complete handrails and kick plates

- Retractable access ladder to chassis

- Clamp-on cone feed hopper c/w Overflow chute to return conveyor

- Movable cable wraps mounted on hand rails

- Air to Oil cooler and Positive air pump mounted on front of chassis

- 36” feed conveyor w/ hydraulic side shift top & bottom for operating and travel positions

- Tramp metal protection magnet on feed conveyor

- 42” discharge conveyor with hydraulic raise and lower on return conveyor

- 12 Volt Hydraulic plant leveling - Two (2) 50,000 lbs cylinders

Cone Crusher:

- Sandvik CH440 Hydrocone Crusher

- ASRi 2.0 computer automated cone control

- 300 hp drive motor

Optional Equipment:

- Hydraulic raise and lower cone feed on discharge end

The Sandvik CH440 Cone crusher is an advanced design that features a small footprint and high capacity in relation to size. The CH440 offers high reduction efficiency and very good product shape.

The Sandvik CH440 Cone crusher is an advanced design that features a small footprint and high capacity in relation to size. The CH440 offers high reduction efficiency and very good product shape.