- About

- Equipment

- Parts

- Service

- Contact

- Blog

- In-Stock

- Mining

- Resources

- Photo Gallery

Cast-in-carbide for the toughest conditions

Cast-in-carbide for the toughest conditionsHX900 is a unique wear material combining the wear resistance of cemented carbide with the shock resistance, ductility and forming capability of nodular iron. This is an ideal combination resulting in a hard material that stands well in tough environments and has a long wear life.

Used in a wide range of applications, HX900 is implemented in the mining and mineral handling industries, steel works, concrete plants and in road maintenance. It has found use most readily in crushing, fragmentation and grinding operations. In such applications HX900 can easily replace conventional wear resistant steels, castings and hardfacing on wear parts subjected to severe stresses.

The high wear resistance of HX900 makes it a material that contributes to new opportunities for improved product quality, reduced down-time and increased productivity.

A typical HX900 product has a wear resistance that is comparable with cemented carbide and a strength that is 80-90% of the strength of pure nodular iron. The wear resistance is generally 3-15 times higher than with common structural steel, nodular iron, welded material or ceramics. HX900 can be produced in various shapes and sizes and can be used in many different types of applications. The composition of the material can be optimized to meet the specifc requirements for each application. That makes it a exible and durable material.

HX900 is produced in the form of composite or clad. The casting method used in both cases provides a metallurgical bond between the cemented carbide granules or tiles in the wear zone and the nodular iron in the base metal. It is also possible to have a mixture of composite and clad.

To create the composite of HX900, granules of cemented carbide are added to the nodular iron surface. Composite is ideal to use in products that will be exposed to heavy impact. Approximately 50% of the composite wear zone consist of granules. The granules have a size of 1 to 6 mm (0.04-0,24”), depending on the application and thickness of 5 to 20 mm (0.2-0.79”).

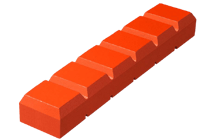

HX900 clad products consist of cemented carbide tiles embedded in the nodular iron surface. The tiles form an almost continuous surface and provide the best protection against wear due to abrasion and erosion. The tiles can be of various shapes and sizes but are usually rectangular with a length and width of 10 to 50 mm (0.39-1.97”) and thickness of 2 to 10 mm (0.08-0.39”).

Typical applications include:

Crusher arms • Loader Buckets • Chutes • Rock Boxes • Edge Protection • Excavators • Weld On Hammer Tips • Breakers / Hammers • Heel Plates • Truck Boxes

Weldable segments are suitable for any place that would otherwise be inaccessible for the installation of wear liners.