The machine central to almost every crushing spread is the cone crusher and there are two basic families of cone crushers; top adjusting bearing cones and bottom adjusting bushing cones. For operators who are considering the purchase of a cone, it is important to understand differences between the two types – especially, production, parts and maintenance implications.

The machine central to almost every crushing spread is the cone crusher and there are two basic families of cone crushers; top adjusting bearing cones and bottom adjusting bushing cones. For operators who are considering the purchase of a cone, it is important to understand differences between the two types – especially, production, parts and maintenance implications.

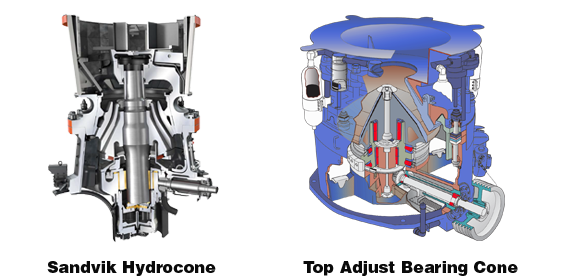

The most popular versions are the Sandvik Hydrocone (Bottom Adjust Bushing Cone) and the JCI and Cedar Rapids Cone Crushers (Top Adjust Bearing Cones). We will compare these in this article.

Construction

The Sandvik Cone is a simpler design and has fewer moving parts. It is supported at both top and bottom, and the head assembly is raised from the bottom by a hydraulic piston to adjust the closed side setting.

The bearing cone is only supported at the bottom and the top or bonnet is vertically adjusted by rotating the threaded bonnet support within the threaded lower section to adjust the closed side setting.

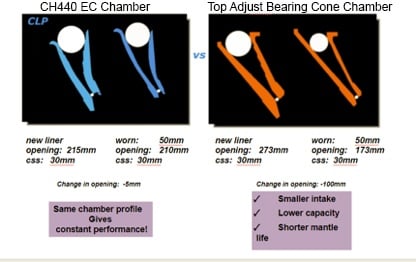

Constant Liner Performance (CLP)

The physics of the bottom adjust cone are different than a top adjust cone as the maximum feed size remains constant throughout the life of the liner on the bottom adjust cone crusher. Feed size in top adjust cones shrinks as the liner wears automation

The physics of the bottom adjust cone are different than a top adjust cone as the maximum feed size remains constant throughout the life of the liner on the bottom adjust cone crusher. Feed size in top adjust cones shrinks as the liner wears automation

Both systems may have automation. One main difference is the Sandvik cone is the only cone adjustable under full load with no damage or maintenance implications on V seats and threads. The Sandvik cone does not have V Seats so there is no possibility of this type of damage.

Adjustable Throw

The Sandvik Cone has an adjustable eccentric bushing that allows the operator to adjust the throw of on the head center/mantle. This allows the operator to optimize throw so that production and product shape are maximized in any application. Bearing cones do not have this capability.

Chamber Configuration Flexibility

Sandvik offers much more choice in crusher chamber configurations to provide more precision adjustments to get the size and shape product you need. Combined with the adjustable throw, the Sandvik cone becomes the most versatile crusher.

Tramp Iron/Uncrushable Relief Differences

If an uncrushable object enters the cone, it can result in significant damage to the crusher. Both types of cone crusher deal with un-crushable material differently.

With the Sandvik cone, the ASRi automation package detects an un-crushable object in the crusher by continually monitoring hydraulic pressure. When it detects an uncrushable object, it lowers hydraulic pressure and the main shaft is lowered. The uncrushable object then falls out of the crusher and onto the discharge belt. Once the uncrushable object is out of the crusher, the ASRi, raises the head back into position to achieve the desired closed side setting.

When an uncrushable object enters the top adjust bearing cone the forces become so great the hydraulic cylinders and/or springs holding the crusher together open and allowing the uncrushable object to exit the crusher onto the discharge belt.

The difference between these two uncrushable relief systems is wear on important parts. The V Seats on the bottom adjust bearing cone snap together with great force after the uncrushable object exits the cone crusher. This wears the V seats every time. The Sandvik crusher does not have V Seats so there is no excessive wear.

The tramp iron relief system on the Sandvik crusher is primarily internal and the Sandvik’s hydraulics are underneath the crusher so they are not exposed to the environment. The bearing cone has considerably more exposed high pressure hydraulic lines and cylinders can rupture and cause injury to employees or environmental contamination from the hydraulic fluids. The external hydraulics on a bearing cone are another item requiring maintenance.

Regular Maintenance Cost Differences

1. Threads and V Seats

Threads and V Seats are a maintenance and repair item on all top adjust cones, bearing or bushing types. Every time the cone is adjusted or relieves an uncrushable object, these parts wear. The Sandvik cone does not have Threads or V Seats.

2. Rebuild Costs

In the event of a cone failure due to ingestion of a large uncrushable object the cone cannot pass, the cost difference of repairing a Sandvik Cone vs. any top adjust bearing cone is stark. In extreme cases the cost is as much as 2-3 times the Sandvik cone.

3. Most maintenance and repairs can be done in the field

Because of its simpler design, most maintenance and repairs of the Sandvik cone can be done in the field. You don’t have to transport the Sandvik cone a shop with cranes as often as a top adjust bearing cone.

4. Repair costs and complexity

The Sandvik cone does not require as many crane lifts as a top adjust cone in its disassembly.

The Sandvik cone has a much simpler design making it easier to maintain. For example, there is no heating or freezing (dry ice) required to assemble or disassemble the Sandvik cone. All parts are a straight lift which speeds up any maintenance or inspections, and the lifting tools come with the crusher. There are fewer components in the Sandvik cone requiring wrapping and/or kept out of the elements when you are doing an inspection.

For these reasons, a wise operator should consider the annual implications for operating a Sandvik vs a bearing cone and bear in mind how those costs will add up over the lifetime of the cone.

Learn more about ELRUS/Sandvik Cone Crushers by clicking the link below.